| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

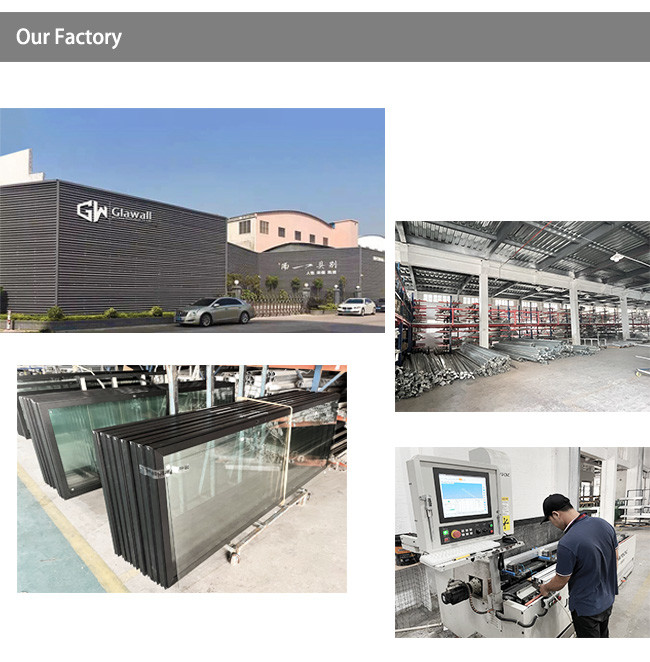

Brand Name : Glawall

Model Number : 100mm ultrahigh style

Certification : SGS, ISO 9001,UL, CE

Place of Origin : China

MOQ : 10 square meters

Price : US$80.00 10 - 99 square meters

Payment Terms : L/C,D/A,D/P,T/T,Western Union

Supply Ability : 3000 square maters per month

Delivery Time : 2-3 weeks

Packaging Details : wooden package

Material : Aluminum frame+glass panel

Transparency : Clear

Customizable : size, accessories

Competitive price : yes

Panel Thickness : 60mm, 100mm

glass type : strong tempered glass

Frame Material : Aluminum

Advantage : Competitive price, good service, high professional, quality guarantee

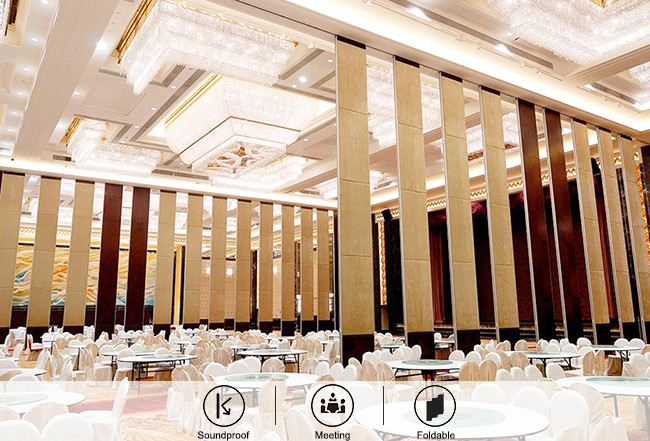

Installation Guide for Extra-High Movable Partition Walls (4m+ Height)

Installing extra-high movable partition walls (4 meters or taller) requires careful planning, structural reinforcement, and precision to ensure smooth operation and long-term stability. Below is a step-by-step guide for professional installation.

| 1. Pre-Installation Planning | |

| A. Site Assessment & Measurements | Verify ceiling height and ensure the space can accommodate the partition system. |

| Check floor and ceiling load-bearing capacity (extra-high walls are heavier). | |

| Identify obstructions (beams, HVAC ducts, lighting fixtures) that may interfere with tracks. | |

| B. Design & Engineering | Custom-track design (straight, curved, or corner-turning) based on space requirements. |

| Decide between ceiling-hung, floor-supported, or dual-track systems (recommended for heights >5m). | |

| Decide between ceiling-hung, floor-supported, or dual-track systems (recommended for heights >5m). | |

| C. Required Tools & Materials | ✔ Laser level & measuring tools |

| ✔ Heavy-duty drill & anchors | |

| ✔ Track system (aluminum/steel) | |

| ✔ Motorized drive system (if automated) | |

| ✔ Sealants & acoustic gaskets | |

| ✔ Lifting equipment (for large panels) | |

| 2. Installation Steps | ||

| Step 1: Ceiling & Floor Preparation | For ceiling-hung systems | Reinforce the ceiling with steel backing or additional supports. |

| For floor-supported systems | Ensure a perfectly level floor; use shims if needed. | |

| For dual-track systems | Both ceiling and floor must be aligned precisely. | |

| Step 2: Track Installation | Straight tracks | Mount the upper track first using laser leveling for perfect alignment. |

| Secure with heavy-duty anchors (concrete or steel). | ||

| Install lower guide track (if floor-supported). | ||

| Curved/corner tracks | Requires custom-engineered curved rails. | |

| Test movement before panel installation. | ||

| Step 3: Panel Installation | Use a panel lift or suction handles to safely position tall panels. | |

| Attach panels to the trolleys/hangers in the track. | ||

| Ensure panels interlock properly for acoustic sealing. | ||

| Step 4: Motorization & Automation (If Applicable) | Install motorized drive units (chain, belt, or gear-driven). | |

| Set up control systems (remote, touch panel, or smartphone app). | ||

| Test safety sensors (obstruction detection, emergency stop). | ||

| Step 5: Sealing & Finishing | Apply acoustic seals (top, bottom, and between panels). | |

| Install end caps and covers for a clean finish. | ||

| Test multiple opening/closing cycles for smooth operation. | ||

3. Post-Installation Checks

✅ Structural Stability – No wobbling or misalignment.

✅ Smooth Movement – No jerking or sticking.

✅ Soundproofing Test – Check for air gaps or leaks.

✅ Safety Features – Sensors and emergency stop working.

4. Common Challenges & Solutions

| Issue | Solution |

| Panel misalignment | Recheck track leveling with a laser. |

| Motor jamming | Ensure proper voltage and lubrication. |

| Noise during movement | Adjust rollers or replace worn bearings. |

| Gaps in soundproofing | Add extra seals or adjust panel alignment. |

5. Maintenance Tips

Lubricate tracks & rollers annually.

Inspect seals for wear and tear.

Test automation systems periodically.

Conclusion

Installing extra-high movable partition walls requires precision engineering, reinforced structures, and professional handling. When done correctly, they provide seamless, soundproof, and automated space division for large venues.

Need a recommended supplier or detailed technical specs? Let me know!

|

|

Extra-high Movable Partition Walls With Installation Guide Soundproof Movable Wall Images |